Interview with Marco Bugatti, CEO of BMB

BMB was founded in 1967 as a family-run business with a clear vision: to develop plastic injection moulding machines that combined technology, precision and reliability. Over the decades, the company has experienced key milestones, from the introduction of numerical control in the 1980s to the launch of its first fully electric machines, which marked a major step forward in efficiency and sustainability. Today, it remains a company with a distinctly Italian identity and a strong international outlook, committed to innovation and close, attentive customer service.

The company is regarded as a global reference in injection moulding machines. What sets BMB’s solutions apart from others on the market?

BMB machines stand out for offering high performance and exceptional precision while keeping energy consumption remarkably low. Our philosophy has always been to deliver maximum output with minimal impact. We also place great importance on customisation: every machine is designed around the customer’s specific requirements. This flexibility, combined with mechanical reliability and energy efficiency, defines who we are and differentiates us from the competition.

Innovation is one of your core pillars. What R&D areas is BMB currently focusing on to continue delivering cutting-edge technology?

Our R&D team works continuously to anticipate market needs. Right now, we’re concentrating on improving electric and hybrid drive systems, advancing process digitalisation and integrating solutions that support the circular economy. We are also pushing ahead with predictive maintenance and data analytics to optimise performance and prevent unplanned downtime. Our goal is to provide machines that are increasingly intelligent, efficient and sustainable.

Your machines are known for their precision, reliability and energy efficiency. How do these qualities translate into tangible benefits for customers?

For our customers, this means more stable processes, lower energy use and consistently high product quality. BMB machines ensure extremely fast and repeatable production cycles, reducing waste and boosting profitability. Their energy efficiency leads to significant savings, while the accuracy of the injection system guarantees flawless results, even in the most demanding applications. Ultimately, customers achieve higher productivity with fewer resources.

Sustainability is becoming increasingly central in the industry. How does BMB integrate efficiency and environmental responsibility into its processes and products?

Sustainability is part of how we think. We design our machines to consume less energy and to work with recycled materials or biopolymers without compromising performance. Our fully electric lines are a clear example: they substantially reduce energy consumption and indirect emissions. Within the company, we also apply internal efficiency and recycling policies, because we believe innovation must go hand in hand with respect for the environment.

Beyond technology, BMB places strong emphasis on customer service. What added value do your consultancy, technical support and training programmes offer?

Our aim is to support the customer throughout the entire journey, from the initial project stage to day-to-day maintenance. We provide personalised technical consultancy, hands-on training for operators and fast assistance both on-site and remotely. We want every customer to get the most out of their investment and to feel supported at all times. Ultimately, long-lasting relationships are built not only on machines, but on trust.

The company has an international network of subsidiaries and after-sales services across different markets. How important is customer proximity in your business model?

Customer proximity is vital. Having a direct presence in Europe, the Americas and Asia enables us to offer quick, tailored support in each market. It’s not just about being physically close; it’s about listening, understanding and responding. This personalised approach allows us to adapt to the specifics of each region and maintain the level of service excellence that characterises BMB worldwide.

Which industrial sectors are currently driving demand for BMB solutions, and what new growth opportunities is the company exploring?

We are seeing strong demand in the packaging, medical and technical-industrial sectors, where precision, speed and efficiency are crucial. Sustainable packaging, in particular, is driving significant innovation. At the same time, we are exploring new opportunities in applications using recycled or biodegradable materials, as well as in emerging markets seeking advanced technological solutions. We aim to grow by supporting our customers as they transition towards more responsible and competitive production.

Equiplast brings together the most innovative companies in the plastics, chemical and rubber sectors. What new developments will BMB showcase at the next edition of the event, and what are your expectations?

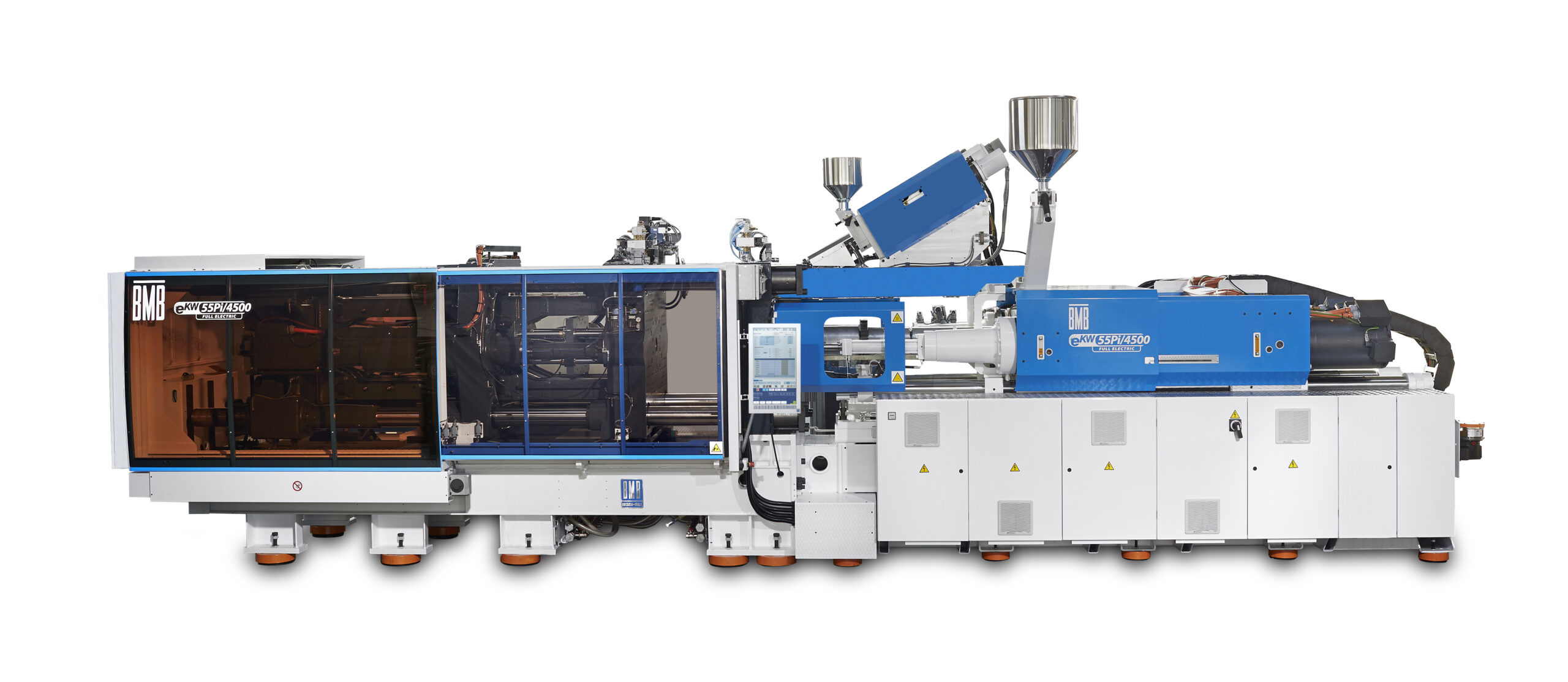

At this edition of Equiplast, we will unveil our new eKW Hybrid HP machines, which represent BMB’s evolution towards ultra high-performance hybrid solutions.

The HP model is designed for high-speed packaging applications, where precision and extremely short cycle times are essential. Dedicated to thin-wall parts, it delivers speed, stability and energy savings.

We expect Equiplast to be an excellent opportunity to present these innovations first-hand, strengthen our presence in the Iberian market and connect with customers seeking advanced, efficient and sustainable technologies.

What role do you think Equiplast can play in strengthening BMB’s presence in the Iberian market and across southern Europe?

Equiplast is a strategic platform for reinforcing our presence in Spain and southern Europe—regions that are strongly committed to industrial modernisation and sustainability. Events like this allow us to build closer relationships with local customers, understand their new challenges first-hand and show how BMB technology can help them overcome them. It is an ideal space for consolidating partnerships and opening up new collaboration opportunities.