Interview with Juan María Cerdá, Founder of Protecnic 1967

Protecnic 1967 is a family-owned company based in Barcelona that focuses on sustainable growth, the circular economy, and business resilience. A pioneer in the 1970s by introducing recycling in Spain, it expanded its collaboration in plastic processing (film, sheet, pipes, and profiles) in the 1980s. Today, it stands out for a 360º service covering everything from initial consultation and installation to commissioning, training, after-sales support, and spare parts. This year, it will once again be a Global Partner of Equiplast, reaffirming its strong commitment to the sector’s future.

Protecnic 1967 has gone through various phases since its foundation. What changes have shaped the company’s journey and specialisation within the plastics sector?

We began in the petrochemical plastics sector, but already in the 1970s, in collaboration with Previero-Sorema, we sold Spain’s first plastic recycling installations.

In the 1980s, we expanded our collaboration with companies in plastic processing, in sectors such as film, sheet, smooth and corrugated pipes, profiles… and in 1986 we began our journey with Erema, now the absolute global leader in machinery for recycled plastic extrusion.

For the past 7-8 years, we have also had an exclusive department dedicated to supporting all the brands we represent, allowing us to provide closer and more specialised technical support.

What sets you apart in such a competitive market?

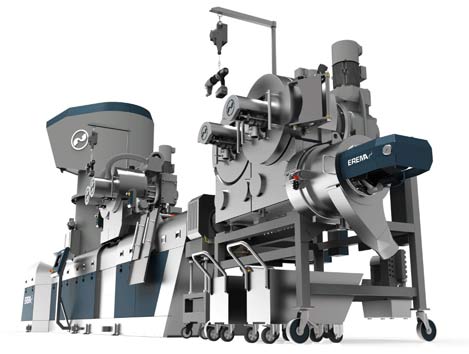

Our differentiation is based on two main pillars. On the one hand, we work with a broad portfolio of top-tier manufacturers, established and specialised in their fields, as it is crucial for us to select partners that provide reliable and technologically advanced solutions.

On the other hand, we offer a 360º service beyond machinery sales, supporting the client throughout the entire process: from initial consultation, installation, commissioning, training, after-sales support, and spare parts. This proximity and continuity in service is something our clients value greatly.

We also continually invest in training our technical team to ensure increasingly specialised and efficient support.

What initiatives or developments is the company driving to improve energy efficiency, circularity, or environmental impact?

At the time, we already selected partners who lead in these areas, offering our clients solutions notable for their innovation and the results they deliver, with equipment incorporating technologies that optimise energy consumption and facilitate material reuse.

For example, the Advanced Recycling campaign by our represented company EREMA promotes advanced recycling in its mechanical processes (and in some cases chemical processes), allowing the processing of highly contaminated post-consumer waste as well as industrial and commercial waste. In doing so, it closes the materials loop and promotes a truly circular economy.

From your perspective, what are the main challenges facing the plastics sector in the coming years, and how is your company preparing to meet them?

The plastics industry in Europe faces major challenges such as the volatility of raw material prices, creating uncertainty in production planning and costs. Other challenges include stricter regulations requiring 100% recyclable packaging and minimum recycled material quotas, alongside pressure to reduce emissions and advance towards a circular economy. Additionally, digitalisation and energy efficiency are key to achieving the goals of the European Green Deal.

We focus on cutting-edge technologies and comprehensive solutions that optimise resources, reduce consumption, and facilitate both advanced processing and recycling. Thanks to our 360º service and close client relationships, we can adapt to regulatory and market changes, offering personalised and competitive solutions.

Which technological trends do you think will shape the future of plastics processing?

I believe the future of the sector will be marked by increasingly automated and connected processes, a focus on higher energy efficiency, and the ability to work with recycled materials and biopolymers. I also foresee progress towards more precise quality control during production, design for recyclability, and gradual adaptation to new environmental regulations.

What are your company’s strategic priorities to continue growing?

Currently, the most important points are to trust and collaborate with our partners to remain at the highest levels, maintaining and growing our market share. Therefore, we strive for greater innovation growth, which will allow us to seek new applications and expand the sectors served by our represented companies.

Can you share any recent success stories that reflect the added value Protecnic 1967 offers its clients?

We have numerous cases where waste has been transformed into a final manufactured product, such as film for rubbish bags, sheet for light thermoformed products, pipes for double-wall corrugated pipes, profiles, and injection-moulded parts for sectors like construction, automotive, and logistics, among others.

We completed a specific project where dirty plastic waste, from injection and blow-moulded materials, went through shredding, washing, drying, mixing, extrusion with decontaminating filtration, and injection moulding, resulting in lightweight pallets and, in some cases, depending on material quality, heavy-duty pallets.

What objectives have you set for 2026?

We have three clear goals: lead the transition to total plastic circularity, accelerate the digital transformation of production plants, and position ourselves as a trusted partner for our clients.

How do you value interaction with clients and collaborators at an event like Equiplast? What kinds of synergies do you aim to generate?

We value it very positively, as it allows us to understand potential clients’ needs first-hand, present our solutions, and showcase the latest innovations from our represented companies. These encounters are crucial for connecting, listening, and adding value to our clients’ production processes, as well as identifying key sector challenges and exploring opportunities to expand into related sectors.

What does it mean for Protecnic 1967 to be a Global Partner of Equiplast?

For us, being a Global Partner of Equiplast is not just about having a space at the exhibition; it is a statement of our commitment to the future of the plastics sector. In fact, it signifies three fundamental things: firstly, consolidating our leadership position as a reference player in the industry, sharing vision with the best, and supporting a forum that drives industrial transformation. Secondly, a commitment to innovation, as Equiplast showcases the circular economy and digitalisation, and our role as global partners places us at the heart of this conversation, helping to chart a path towards more efficient and sustainable production. Finally, client proximity: it is the perfect setting to hear first-hand the challenges of our clients and collaborators nationally and internationally, reaffirming that Protecnic 1967 not only provides solutions but accompanies the sector in its continuous evolution.

Which products or solutions will you highlight at the fair?

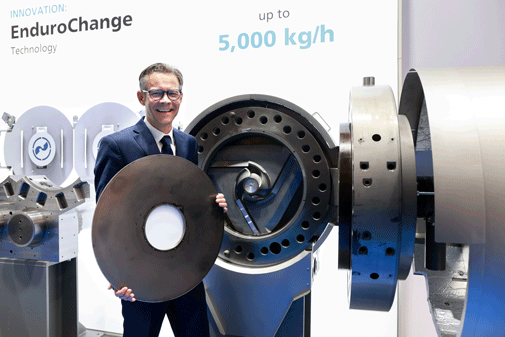

We present solutions from several of our represented companies. From EREMA, we highlight the VOLEX technology, which reduces volatile organic compounds (VOCs) by 40% through water injection in an extruder; AGGLOREMA, a new recycling system specially developed to process highly contaminated post-consumer waste for chemical recycling; TwinPro, a high-performance twin-screw technology for single-step recycling of complex low-density films; and the new LASER FILTER 812 model, with double the filtering surface compared to the 406 model and a filtration capacity of up to 5,000 kg/h of molten mass.

Regarding PREVIERO-SOREMA solutions, we will showcase a new TRAY to TRAY recycling system, starting from post-consumer PET trays, producing extremely high-quality flakes. We will also present the new WKS shredding model from WEIMA, specifically designed for film.