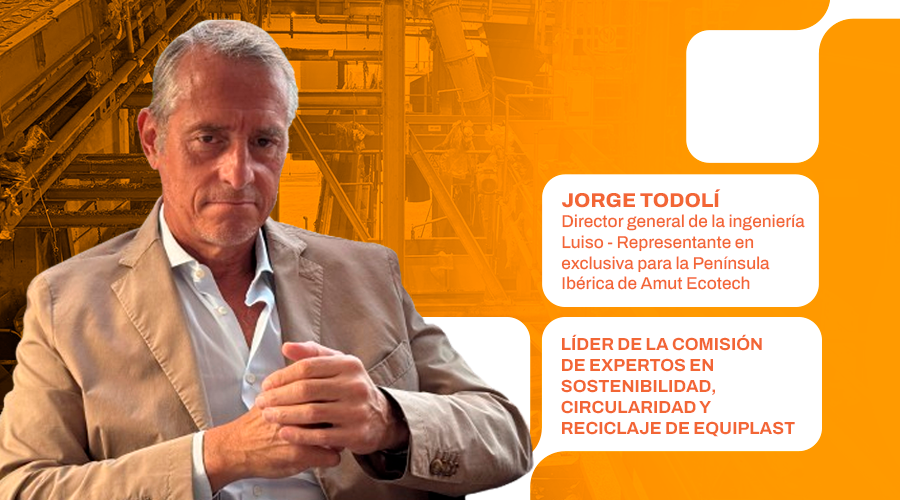

Interview with Jorge Todolí, head of the Expert Committee on Sustainability, Circularity and Recycling at Equiplast

Equiplast 2026 has set up a committee of experts made up of representatives from the machinery industry, recyclers, processors and organisations committed to promoting sustainability, circularity and plastic recycling in Spain. Leading the initiative is Jorge Todolí, Managing Director of the historic engineering company Luiso – exclusive representative for Amut Ecotech in the Iberian Peninsula. The project also brings together companies such as Douma, Protecnic, Remondis, Veolia, 2G Chemical Plastic Recycling and Congost/Rototank, along with private and public institutions (Anarpla, Anaip, Aimplas, the Spanish Plastics Centre, ASEGRE, the Catalonia Waste Cluster, ACCIÓ and Eurecat).

In this interview, Todolí explains the committee’s goals and how the reimagined Rethinking Plastic space will help promote better understanding and best practices around plastics.

What is the main challenge facing plastics in today’s context?

I’d like to clarify that, interestingly, plastics are not really a “sector” as such, because they are present in almost every industrial sector, even though we have never managed to institutionalise them as one.

That said, the first challenge our committee has set itself is to demonstrate that plastics are not society’s, nor ecology’s, number one enemy. It’s true that if waste in general is not properly managed and controlled, it harms the environment – and when that happens, it’s all too easy to scapegoat plastics. Yet plastics have replaced many natural raw materials, helping to prevent deforestation and excessive energy consumption.

What other major challenges lie ahead?

We want to highlight the fact that plastics processing is a prime example of flexibility and circularity, having revolutionised production processes across industry. Using recycled plastics within the same process enables us to remove waste from the environment while gradually reducing the use of virgin plastic, which is a petroleum derivative.

That’s why it’s so important to promote the creation of recycling plants, or to encourage plastics processors across all industries to also become part of this recycling chain.

How are new technologies helping the plastics industry meet today’s challenges of sustainability and efficiency?

Nowadays, with artificial intelligence and advanced visual and optical systems that identify and separate different types of plastics throughout the chain, together with chemical and mechanical recycling… technology has taken us to points that were very difficult to reach just a few years ago. We are now able to reuse almost all of the plastic that can be collected.

The most important thing is traceability: following the recycling process from the moment waste is collected right through to its transformation into a new product.

How does Spain compare with other European countries in terms of plastic recycling, and where are the growth opportunities?

Spain is the second European country in terms of per capita recycling rates, behind only Germany. At present, 70% of recycling is carried out privately: most recycling centres are run by large plastics processors and consumers who set them up to recover their own material.

That said, between 30% and 40% of the recovered plastic consumed in Spain each year is imported, largely because it is cheaper, less strictly controlled, and more heavily subsidised elsewhere. Recycled plastic is increasingly scarce in Europe, so companies often end up buying it from China.

Another factor is that Spain’s population multiplies exponentially for almost half the year, especially along the coast. This generates a huge volume of waste from this temporary population, which consumes significant amounts of energy during their stay. They create waste and pollution, and Spain should be a leader in harnessing that waste – transforming it into raw plastic material or into energy.

What is the committee’s view of the role public administrations should play in promoting plastics sustainability, circularity and recycling?

It’s crucial that regulations are harmonised, with at least the same rules applying across all European countries. Otherwise, we end up with large volumes of recycled plastic imported from countries where legislation is much less strict or demanding.

In Spain, more support and engagement from the administration are needed, along with greater clarity regarding certain measures. In this respect, joint public-private committees are essential for clarifying what actions are going to be taken and avoiding problems like those caused by the single-use plastics ban.

What role will the Rethinking Plastic space at Equiplast 2026 play in conveying these needs to public authorities?

At Rethinking Plastic we hope to see participation from key institutional stakeholders. It would be especially valuable if ministries such as Ecological Transition and Industry were to take part in some of the events and conferences scheduled during the fair, acting as a link between government and business to advance training and education.

This space will also give the administration the opportunity to explain the regulations it is applying now and those planned for the future.

How will Rethinking Plastic help promote knowledge and best practices across different industrial sectors?

For the 2026 edition, we are preparing a programme of highly relevant talks, drawing on the expertise of the recycling chain, to serve as a guide for processors. They will see that the major draw of Expoquimia and Equiplast is now opening up towards recycling – which will give it added strength.

We are offering something extra, by sharing regulation, waste management, and experiences in palletisation, pre-sorting, washing, and more.

The expert committee you lead at Equiplast brings together some of the most representative companies and organisations in this growing field. What are your priorities?

The committee is broad and well represented by the country’s leading associations. Several of the top players in each segment in Spain, and in some cases at European level, are also involved. We would also like to add at least two major national recyclers to the group.

During our committee meetings to prepare for Equiplast 2026, we saw great value in integrating plastics recycling into the event, aiming to create a major exhibition space where everyone can take part, both as exhibitors and as clients.

What sets us apart from other European congresses and fairs is that here we will bring together the entire value chain: from machinery manufacturers (Equiplast) to chemical industry raw material producers (at Expoquimia), and including recycling as a third pillar of the fair. In this way, we can offer visitors a complete vision of what the circular economy really is.